Vibration is one of the best monitoring parameters for rotating machines. If the condition of a machine changes, its vibration pattern changes too. The change in condition can be caused by a fault in machine components such as bearing, coupling, rotor, foundation, etc. Moreover, any change in the machine’s operational status can also make a change in its vibration pattern. This can include change in load, speed, flow, pressure, and any other operational parameter. So, most industrial plants use vibration monitoring programs to detect any potential problem in their rotating machines whether caused by a machine fault or a change in the operation.

In this post, the major steps of developing and implementing a vibration monitoring program are briefly discussed. This includes selecting the machines, the measurement points, and the vibration parameters, developing a database, creating a measurement plan and running it, analyzing the acquired data, and preparing reports. All of these steps should be considered as a dynamic plan that needs time-to-time audit after the first implementation. This will guarantee continuous improvement for the program.

1 – Selecting machines

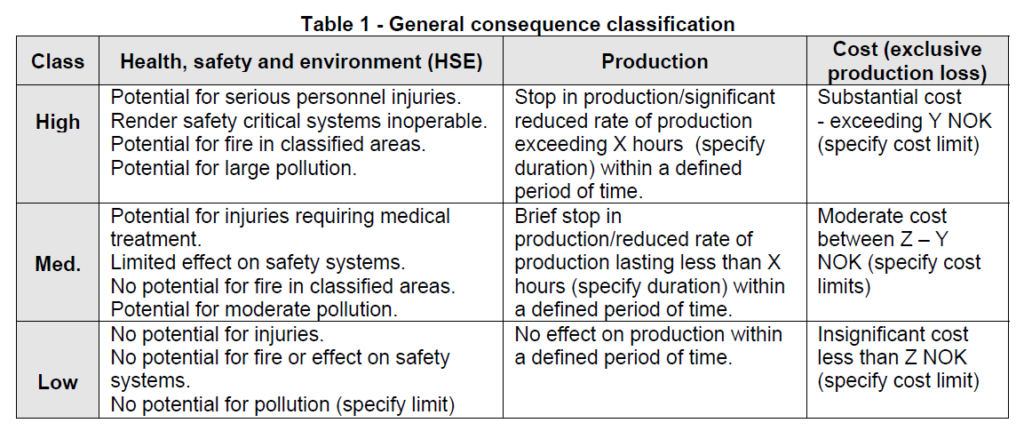

In this step, the desired machines are selected to be included in the vibration monitoring program. This is usually done based on the machine criticality. A machine criticality is determined considering the effect of machine failure on production, maintenance, safety, environment, and quality. Table 1 shows an example of this classification based on the consequences of machine failures.

Machines criticality is usually categorized as high, medium, and low. Norsok Standard, Z-008 can be used as a reference for equipment criticality analysis. Table 1 is extracted from this standard.

2 – Selecting measurement points/directions

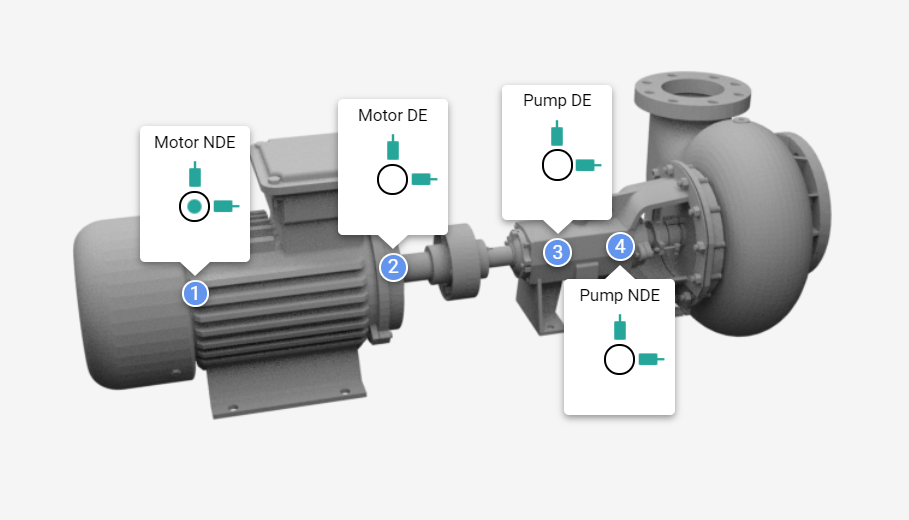

Vibration data are collected from machine bearing housings in axial, horizontal and vertical direction. Machines such as electric motors, pumps, and fans usually have two bearings which are located in machine casing or bearing housings/pedestals. The rotor can be positioned either center-hung or over-hung in the bearings. For example, this picture shows a center-hung electric motor and an overhung pump that altogether has 4 bearings which means 4 vibration measurement points.

For some more complicated machines such as gearboxes or some kind of compressors you may need to find out the bearing locations using machine drawings.

Vibration should be measured from all 3 directions, axial, horizontal and vertical as different machine’s problems may generate different vibration patterns with regard to direction. If you do not measure vibration from some directions (e.g. axial), you may miss some faults that are captured better in that direction (e.g. bent shaft, cocked bearing).

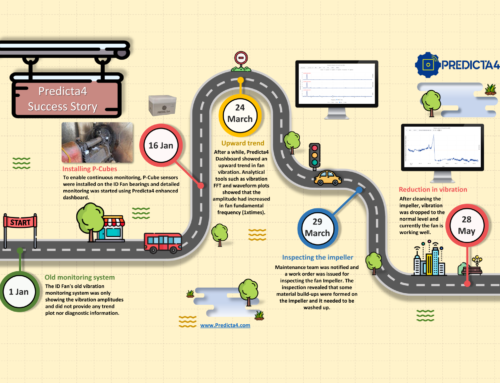

3-axis vibration sensors (e.g. P-Cube) are good choices as they measure vibration from all 3 directions at the same time.

At the end of step 2 and 3, you should have a list of selected machines in hand that you have chosen the measurement points for each of them. It is a good idea to put a mark on each measurement point to collect the data exactly from the same point.

3 – Selecting vibration monitoring parameters

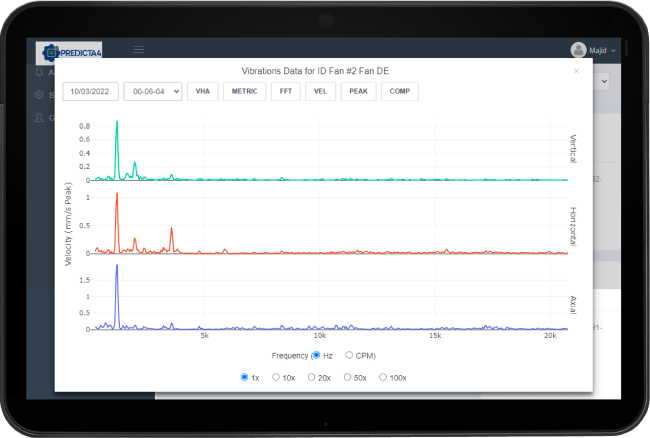

Generally speaking, vibration is a complicated quantity and there are a lot of vibration parameters that can be chosen for monitoring and detecting machine faults/problems. But, to keep it simple, parameters such as overall velocity (RMS or Peak) and overall acceleration (RMS or Peak) are the right parameters that work for most of the machines and can discover most of their problems. For more complicated machines or low/high speed machinery or machinery with fluid-film bearings, you may need to consider some other monitoring approaches such as spectrum band or diagnostic monitoring. Moreover, analytical tools including FFT, time waveform, demodulated spectrum, and orbit are needed for diagnosing the potential problems.

4 – Selecting vibration measurement instruments

There are 3 different categories of vibration measurement systems:

- Wired on-line vibration monitoring systems

- Portable vibration data collectors/analyzers

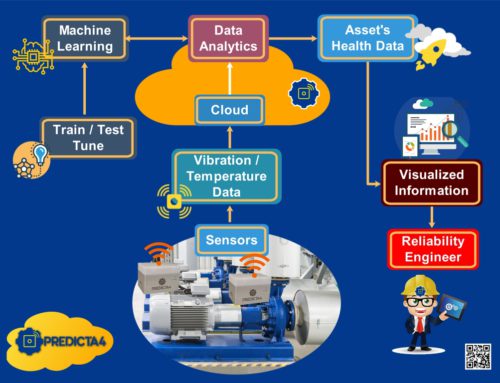

- Wireless cloud-based vibration monitoring systems (e.g. Predicta4)

In fact, a right combination of these systems may provide the best solution for you. Machines with high criticality may be considered for wired on-line vibration monitoring and those with medium criticality are candidates for vibration monitoring using portable data collectors.

Vibration monitoring using wireless vibration sensors (e.g. P-Cube) can be considered for machines with both high and medium criticality, as a substitute for the traditional methods. These new generations of vibration monitoring systems are more cost-effective and easier to implement, compared to both wired on-line systems and portable data collectors.

5 – Developing measurement plan and running it

Vibration data is collected continuously, in wired on-line monitoring systems. But, for portable data collectors and wireless monitoring systems, you should develop a measurement plan including how frequently vibration data should be collected.

The frequency of data collection with portable instruments depends on several factors including machine criticality, machine duty cycles, access to the machine, and available resources. On average, monthly data collection is a right choice for most machines. You will also need a plan for how machines should be put into different measurement lists (known as routes) to optimize walking around the machines for vibration measurement. Usually machines with the same measurement schedule and located in the same area/unit are added to the same measurement list (or route).

6 – Developing vibration monitoring database

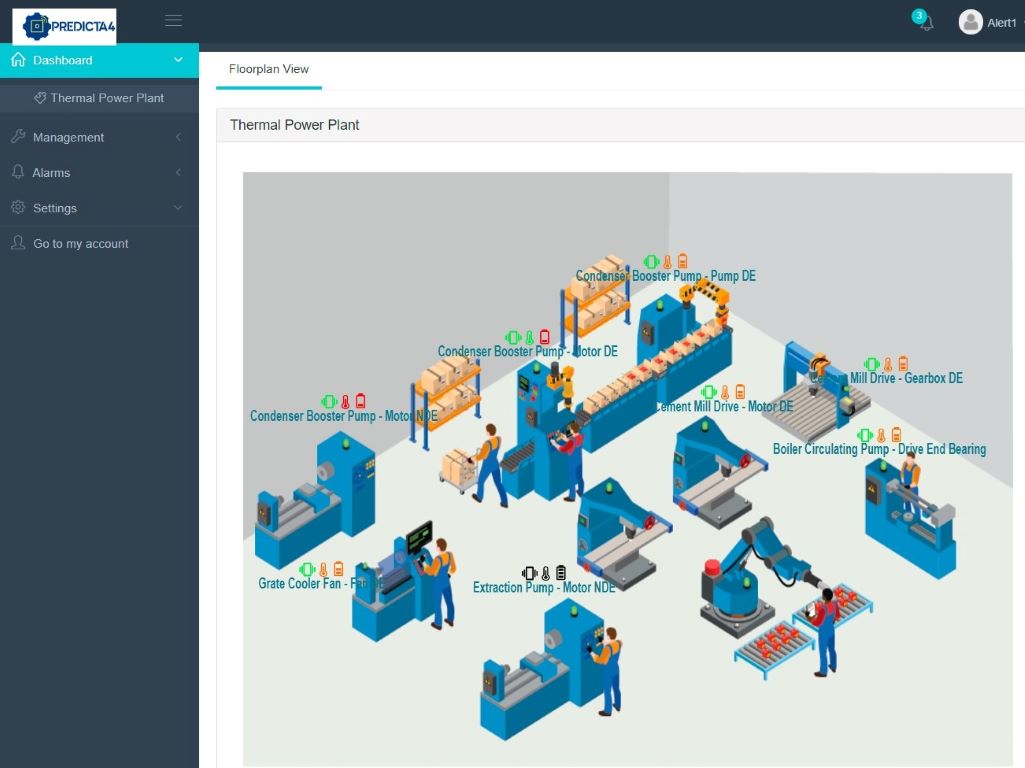

After choosing the vibration measurement points and the required vibration parameters, you can now create the database. This is done using the vibration analysis software and includes creating machines, adding measurement points, adding vibration parameters, and creating measurement lists or routes. You also can define thresholds for vibration parameters and add machine technical information, drawings, photos, and schematics to the software.

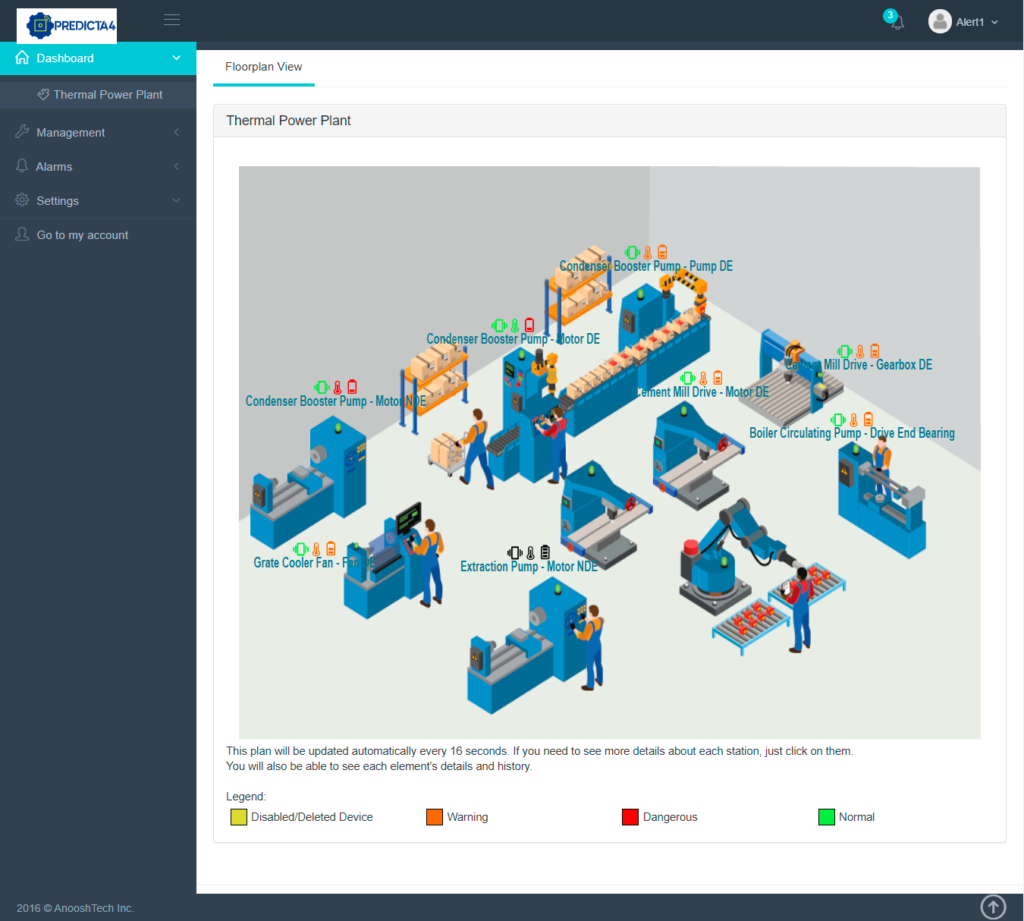

In wireless vibration monitoring systems, all of these steps are done using a cloud-based Dashboard (e.g. Predicta4 Dashboard).

The frequency of data collection with wireless monitoring systems (e.g. Predicta4) usually depends on the battery life. Data can be collected every few minutes or a few times per day (e.g. 4 times per day). One of the major advantages of this type of system is that there is no need for walking around the machines for data collection. This will free up the condition monitoring technicians for doing tasks with more value-added and at the same time, will make it possible to measure vibration in remote or hazardous locations.

7 – Analyzing acquired data

Vibration data which is collected in routine measurements can be categorized into 2 categories.

The first category is the overall vibration parameters which includes overall vibration velocity, acceleration, displacement, crest factor, kurtosis, and much more. This kind of data is suitable for machine condition assessment and detecting the faults. They are usually compared to some predefined thresholds (i.e. Warning/Danger level) and also their trend status is evaluated to see how they are changing over the time.

The second category is the analytic graphs including FFT, time waveform, demodulated spectrum, orbit, etc. This kind of data is suitable for fault diagnosis and pinpointing the problems that have resulted in the abnormal vibration.

The vibration signals collected by portable instruments are stored in the software package sold with the instrument. On the other side, in wireless vibration monitoring systems, data is available via the Internet through some Dashboards, powered by Cloud technology (e.g. Predicta4 Dashboard).

8 – Preparing reports and initiating maintenance request

The last step that should be taken by the condition monitoring team is to prepare general reports about machines status and also technical reports discussing the analysis done in more detail. These reports will inform maintenance and operation teams about the latest condition of the machines and also can be used to initiate the required maintenance activities. They also would help document and keep track of the vibration monitoring program outcomes and benefits.

9 – Continuous improvement

Vibration monitoring is a dynamic program that needs to be audited regularly. You should review all steps of the program from selecting machines to preparing reports, at least once a year. This will help recognize any potential problems and discover improvement opportunities for the monitoring program.

Leave A Comment

You must be logged in to post a comment.